Jib crane arms are designed to be versatile and efficient, with a wide range of applications across various industries.

There are several types of jib crane arms, including fixed jib cranes, which are mounted on a fixed base, and slewing jib cranes, which can rotate 360 degrees.

A key factor in jib crane arm design is the choice of material, with steel and aluminum being popular options due to their strength-to-weight ratio.

The design of the jib crane arm also depends on the type of load it will be lifting, with heavier loads requiring stronger and more robust arms.

Here's an interesting read: Jib Crane Design

Types of Jib Crane Arms

There are two main types of cantilever design options for mast type jib cranes: Full Cantilever and Drop Cantilever. The Full Cantilever design is used when there are no overhead obstructions, allowing for maximum lifting capability and clearance underneath.

The boom is mounted to the top of the mast in a Full Cantilever design, providing maximum lifting capability. In contrast, the Drop Cantilever design allows for clearance for overhead obstructions located below the top of the mast, achieved through side-plate connections.

Here are the key differences between the two designs:

Articulating

Articulating jib cranes offer a unique combination of flexibility and precision, making them ideal for navigating tight spaces. They feature two swivel arms that can lift loads around corners and columns, allowing for a greater coverage area and more flexibility closer to the mast or column.

The primary boom arm of an articulating jib crane allows for 200° swivel, while the outer arm offers full 360° rotation. This provides a significant advantage when it comes to maneuvering loads in tight spaces.

Articulating jib cranes can be mounted in various ways, including floor-mounted, wall-mounted, ceiling-mounted, or mounted on a bridge or track system. This versatility allows for precise load positioning and spotting loads around obstructions.

Here are some key specifications for articulating jib cranes:

- Spans up to 16’

- Capacities up to 1 ton

- 360° rotation for freestanding and ceiling-mounted systems

- 180° inner arm/360° outer arm for wall-mounted systems

For heavier duty and more frequent lifts, articulating jib cranes may not be the best choice, as their design won't allow for higher capacity lifts and their span is somewhat limited.

What Is a Sail?

A sail is actually a term that's not directly related to the jib crane, but it's worth noting that the sail on a sailboat is similar to the jib on a jib crane in that it's a horizontal or angled arm that extends from the main structure. The sail's shape and size determine its ability to harness wind and propel the boat forward, much like the jib's length and angle determine the range and reach of the crane.

The jib crane's arm, also called the jib, is the part that supports and moves the load, allowing it to swing and pivot around the mast. This is similar to how a sail uses the wind to propel a sailboat forward.

By rotating and extending, the jib facilitates efficient handling of materials, such as stone slabs, within its operational radius.

Design and Components

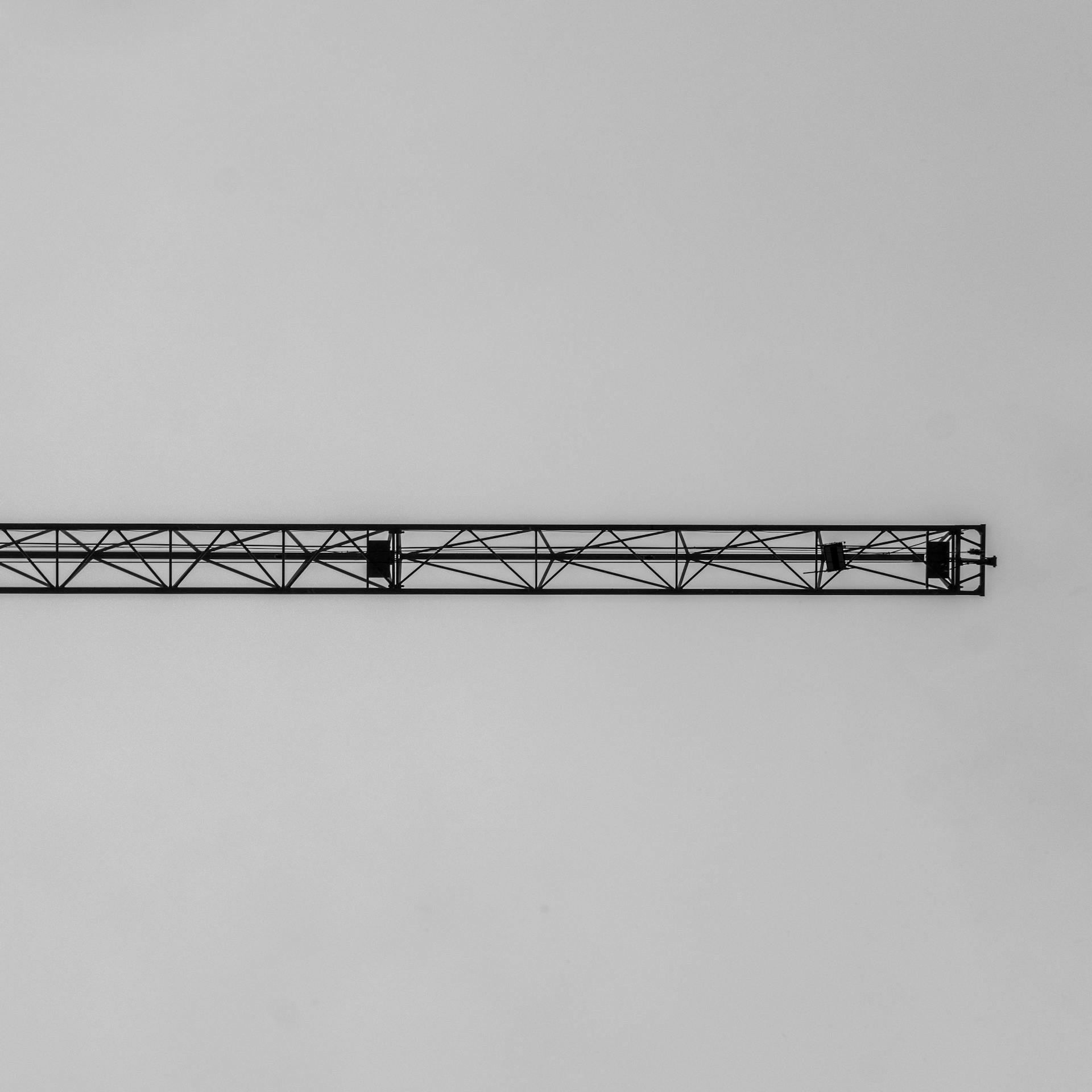

A jib crane arm is a crucial component of a jib crane system, and understanding its design and components is essential for optimal performance. The reach/boom is the horizontal beam that the trolley travels back and forth on.

A jib crane arm typically consists of several key components, including the mast/pillar, movable hoist, trolley, and rotation system. The mast/pillar is the vertical beam used to support the boom on freestanding and mast systems.

The trolley is the motion of the trolley can be manual, motorized, or pneumatic, and it carries the hoist, wire rope or chain, and the hook along the entire length of the boom. The rotation system allows for 360° of boom rotation on free-standing and mast-type jib cranes, and 180-200° of rotation on wall and column-mounted jib cranes.

Here are the main components of a jib crane arm:

- Reach/Boom

- Mast/Pillar

- Movable Hoist

- Trolley

- Rotation

These components work together to provide a reliable and efficient lifting system, making jib cranes a valuable asset in various industries, including manufacturing.

Components

A jib crane's design is straightforward, but its components are what make it functional and efficient. The reach or boom is the horizontal beam where the trolley travels back and forth.

The mast or pillar is the vertical beam that supports the boom on freestanding and mast systems. It's typically made from high-strength steel and securely anchored to the floor or walls.

A movable hoist is used to lift, position, and lower a load, while the trolley carries the hoist, wire rope or chain, and the hook along the entire length of the boom. The trolley's motion can be manual, motorized, or pneumatic.

Rotation is a key feature of jib cranes, with freestanding and mast type cranes offering 360° of boom rotation. Wall and column-mounted jib cranes, on the other hand, offer 180-200° of rotation.

Electrification or pneumatic power can be added to the top or bottom of the mast to provide rotation assistance and allow for continuous 360° boom rotation. Controls can also be added, such as a push-button controller, to control the rotation of the boom, as well as the motion of the trolley and the lifting and lowering motion of the hoist.

A rotation stop can be installed to limit the crane's motion before it collides with a nearby object, especially if the crane is located close to a wall or other obstruction. Environmental considerations, such as corrosion resistance and explosion-proof applications, can also be taken into account when designing the components of a jib crane.

Take a look at this: Wall Bracket Jib Crane

Here's a breakdown of the main components of a jib crane:

- Reach/Boom: the horizontal beam where the trolley travels back and forth

- Mast/Pillar: the vertical beam that supports the boom on freestanding and mast systems

- Movable Hoist: used to lift, position, and lower a load

- Trolley: carries the hoist, wire rope or chain, and the hook along the entire length of the boom

- Rotation: 360° of boom rotation on freestanding and mast type cranes, 180-200° on wall and column-mounted jib cranes

- Electrification/Pneumatic Power: added to the top or bottom of the mast for rotation assistance

- Controls: push-button controller for controlling rotation, trolley motion, and hoist motion

- Hook Height: the maximum height the hook can reach, determined by the lowest overhead obstruction

- Rotation Stop: limits the crane's motion before it collides with a nearby object

Manufacturing

In manufacturing, jib cranes are a game-changer for assembly processes. They're stationed at workstations to support assembly tasks and positioned near production lines for effective material handling and transport.

Jib cranes have significantly alleviated worker strain and enhanced productivity. This is especially true on production lines where substantial equipment is being assembled.

Their straightforward operation ensures that materials are readily accessible, allowing for smoother and more efficient workflows.

Rotation Area

A jib crane's rotation area is a crucial aspect of its design. The rotation area can range from 180° to 360°, depending on the type of jib crane.

For freestanding and mast-type jib cranes, you can achieve 360° of boom rotation. This is thanks to the addition of electrification or pneumatic power, which allows for continuous rotation.

The rotation area also depends on the load movement requirements and the working area available. This means you'll need to consider the space around the crane and the type of loads you'll be lifting.

Here's a breakdown of the typical rotation areas for different types of jib cranes:

In summary, the rotation area of a jib crane is a critical factor in its design and functionality. Understanding the different types of rotation areas and their applications can help you choose the right jib crane for your needs.

Deflection

Deflection is a crucial aspect of design, especially in the context of mechanical components.

A well-designed deflection system can significantly reduce the stress on a component, making it more durable and long-lasting.

In the case of a cantilever beam, deflection is caused by the weight of the load applied to the end of the beam.

The amount of deflection is directly proportional to the length of the beam and the load applied to it.

For instance, a beam with a longer length will experience more deflection than a shorter beam with the same load.

Deflection can be calculated using the formula: deflection = (load x length^3) / (3 x E x I), where E is the modulus of elasticity and I is the moment of inertia.

In a real-world application, a designer might use this formula to calculate the deflection of a beam in a bridge, taking into account the length of the beam, the load applied to it, and the material properties of the beam.

System Types and Options

There are different types of jib crane systems to choose from, each with its own range of capabilities and advantages. Mast type jib cranes are a cost-effective alternative to freestanding systems, requiring only 6 inches of reinforced concrete to support the crane.

Mast type jib cranes typically accommodate 10-40 foot spans, capacities up to 10 tons, 360° rotation, and boom heights up to 40 feet. They can be used for heavy-duty applications, but require an overhead beam or support structure to provide additional support.

Some options and accessories for jib crane systems include fully motorized extension and hoist & trolley packages. These can enhance the functionality and efficiency of your jib crane arm.

Portable

Portable jib cranes are a fantastic option for projects that require frequent repositioning.

They're mounted on a mobile base that can be wheeled or lifted with a forklift, making it easy to move them around.

These cranes typically have a capacity of less than half a ton, which is sufficient for many tasks.

Their design allows a single person to move large quantities of materials without additional assistance.

They're constructed with a lightweight core for easy mobility, enabling them to be positioned close to the work area.

This makes them ideal for projects that involve working in tight spaces or navigating rough terrain.

Portable jib cranes are a great choice for tasks that require flexibility and mobility.

Wall Traveling

Wall traveling jib cranes are a great option for maximizing space in a building or structure. They operate along rails mounted on the walls, allowing for lateral movement of loads.

Their primary goal is to optimize the use of available workspace, enhancing efficiency and reducing the need for additional manpower. Wall traveling cranes can be customized to meet specific needs.

Their lifting capacity ranges from half a ton to ten tons. This makes them a versatile choice for various applications.

Wall traveling cranes can serve as an additional feature or an accessory to overhead cranes.

Intriguing read: Jib Crane Wall Mounted

Hoist

A hoist is the mechanism attached to the boom of a jib crane that performs the lifting operation.

There are various types of hoists designed to meet specific application needs, including chain hoists, wire rope hoists, and lever or ratchet hoists.

Chain hoists utilize a metal chain for lifting, with the chain passing through sprockets and being stored in a container.

Chain hoists are widely preferred because of their cost-effectiveness and minimal maintenance requirements.

They can be powered by manual, electric, or pneumatic means, but their capacity is limited, making them suitable mainly for lighter lifting tasks.

Wire rope hoists lift loads using a wire rope, which wraps around a grooved drum when in operation.

These hoists offer high lifting speeds and can handle loads of 10 tons or more.

Manual hoists are designed for infrequent lifting tasks where rapid speed is not essential.

In manual hoists, one chain is used to lift the load, while the other chain is operated by hand to provide manual power.

Festoon System

A festoon system is used to transport cables and power to the trolley along the boom, ensuring safe and controlled management of power cables.

These systems can be mounted on C tracks, square rails, or I beams, but I beams are the most common for jib cranes.

They safeguard cables from damage and ensure reliable connectivity for jib crane components, which is particularly beneficial for jib cranes with long booms and heavy-duty trolleys.

Options & Accessories

If you're looking to upgrade your system, consider adding a fully motorized extension for added flexibility. This option allows for smoother and more efficient movement.

Some systems also come with a hoist and trolley package, which can be a game-changer for heavy-duty applications.

Hydraulic

Hydraulic systems are a popular choice for cranes, offering a reliable and efficient way to lift and lower loads. They're often powered by a battery or hand pump, making them easy to operate.

A hydraulic jib crane is a great example of this, featuring a hydraulic cylinder that raises and lowers the arm of the crane. The lifting mechanism has a maximum capacity of one ton when the boom is retracted.

Hydraulic jib cranes can be used in a variety of settings, including on the go with a mobile version or stationary with a floor-mounted design. They can also rotate 360°, making them incredibly versatile.

The lifting mechanism of a hydraulic jib crane has a maximum capacity of 500 pounds when the boom is fully extended. This makes them perfect for smaller loads or tasks that require precision.

Power for

Power for jib cranes can be powered by either electrical or pneumatic sources.

The power source is typically positioned at the top of the mast to supply the hoist, trolley, and boom rotation.

Push-button controls manage the crane's movements, including the operation of the hoist and trolley and the boom's rotation.

Crane operators use either a push-button pendant or a wireless control system to manage the lifting, positioning, and lowering of loads.

These controls are designed to facilitate ease of use and precise handling of the load, ensuring operators remain safely out of the load's path.

Rotation Stop

Rotation stops are crucial safety mechanisms designed to prevent a jib crane from colliding with nearby objects or structures. They're a must-have when a crane is positioned near walls or columns.

Fixed rotation stops are permanently welded to the crane's mast to restrict its movement. This provides a reliable and consistent safety feature.

Adjustable rotation stops are also available, allowing operators to configure the limits based on the proximity of surrounding equipment. This flexibility is especially useful in dynamic work environments.

Installation and Foundation

Before installing a jib crane arm, it's essential to prepare a solid foundation. A typical jib crane arm requires a concrete slab foundation that's at least 4 inches thick and 12 inches wide.

The slab should be level and securely anchored to the ground to prevent any movement or shifting. This ensures the crane's stability and prevents damage to the surrounding area.

A jib crane arm can be installed on a variety of foundations, including steel or concrete footings, but a concrete slab is the most common and recommended choice.

Freestanding

Freestanding jib cranes are a popular choice for many industries due to their flexibility and high lifting capacity. They can be installed virtually anywhere, including indoors or outdoors.

One of the key advantages of freestanding jib cranes is their ability to accommodate large spans, with some systems capable of spanning up to 50 feet. This makes them ideal for use in open areas where multiple work cells need to be supported.

There are three main designs for freestanding jib cranes, each with its own unique installation method. The base-plate mounted design is the easiest to install and the most popular choice, as it requires only a reinforced concrete foundation and gussets.

The foundation/insert mounted design is similar to the base-plate mounted design but eliminates the need for gussets. Instead, a welded steel plate at the bottom of the mast is anchored during the first-pour concrete footing, with a second concrete pour supporting the mast.

For more insights, see: Column Mounted Jib Crane

The sleeve-insert mounted design is a bit more complex but offers the added benefit of being relocatable without damaging the mast. A sleeve is welded to a steel plate, which is then anchored to a first-pour concrete footing, with a second pour supporting the sleeve and mast.

Here are the key features of each design:

Freestanding jib cranes offer a 360° rotational capability, making them ideal for use in areas with limited space. This flexibility also makes them a popular choice for use with bridge cranes.

Wall-Mounted

Wall-Mounted Jib Cranes offer a space-saving solution, requiring no floor or foundation support. They can be installed close to the underside of the lowest ceiling obstruction, providing maximum clearance both under and above the boom.

Wall-mounted jib cranes can be designed to swing around obstacles, under obstructions, or fold out of the way of overhead cranes to ensure no interruption of production.

These systems can accommodate spans ranging from 8-30 feet and capacities up to 5 tons. They can also rotate 180°-200°.

Wall-mounted jib cranes can be designed to mount to a wall or building support column in two different ways: cantilever and tie-rod supported.

Related reading: Truck Hitch Mounted Crane

Ceiling Mounted

Ceiling mounted jib cranes are a great space-saving option for lifting heavy loads. They can be installed above workstations to free up valuable floor space.

These cranes are available in standard single boom jib cranes or articulating types, making them suitable for various applications. They can be stationary or platform-mounted, allowing them to serve multiple workstations.

Ceiling mounted jib cranes typically have a lifting capacity of one ton. This means they can handle a significant amount of weight without straining.

Their spans can reach up to 16 feet, providing ample coverage for work areas. This feature is particularly useful in large workshops or manufacturing facilities.

Their 360° pivot range allows for smooth and precise movement. This flexibility is essential for operators who need to maneuver loads in tight spaces.

Foundationless

Foundationless jib cranes are a great option for facilities where a poured foundation isn't feasible. They're slab-mounted and bolted to 6″ reinforced concrete for indoor use.

These types of jib crane systems don't require a special poured foundation, which means they can be installed faster. You don't have to wait for a poured concrete foundation to cure, saving you time and hassle.

Typically, foundationless jib cranes can accommodate spans of 9-16′, capacities up to 1,000 lbs, 360° rotation, and boom heights up to 20′.

Their ease of installation and portability make them a great choice for facilities that need to relocate their jib cranes.

Environmental Factors

Environmental Factors play a crucial role in a jib crane's functionality, and various protective measures can be implemented to safeguard it.

Using galvanized materials can prevent rust, which is essential for long-lasting performance.

Explosive materials require special handling, and installing enclosures can provide a safe operating environment.

Shielding against heat, dust, dirt, and moisture is also vital to prevent damage and ensure smooth operation.

Frequently Asked Questions

What is a jib arm crane?

A jib arm crane is a type of crane that uses a horizontal or near-horizontal beam to support loads clear of the main support. This design allows for greater flexibility and maneuverability in lifting and moving heavy objects.

What is the difference between jib and hoist?

A hoist is a general lifting device, while a jib is a specialized lifting solution that provides precise load positioning along a horizontal axis. Jibs are ideal for applications requiring accurate load placement.

Featured Images: pexels.com