A jib crane is a type of crane that's perfect for small to medium-sized spaces, with a horizontal beam that's supported by a vertical mast. It's great for lifting heavy loads.

There are several types of jib cranes, including wall-mounted, floor-standing, and overhead jib cranes. Each type has its own unique features and advantages.

Wall-mounted jib cranes are fixed to a wall and are ideal for applications where floor space is limited, such as in a small warehouse or factory. They're also great for lifting heavy loads over a fixed area.

Floor-standing jib cranes, on the other hand, are free-standing and can be easily moved to different locations. They're perfect for applications where flexibility is key.

For another approach, see: Wall Bracket Jib Crane

Types of Jib Cranes

Jib cranes come in various types, each with its own set of capabilities and advantages. Mast type jib cranes are a cost-effective option that can accommodate spans of 10-40 feet and capacities up to 10 tons.

Mast type jib cranes don't require a special foundation, just 6 inches of reinforced concrete to support them. They can use an existing overhead support beam or structure for additional support. There are two types of cantilever design options: full cantilever, which provides maximum lifting capability and clearance, and drop cantilever, which allows for clearance under overhead obstructions.

Here are the main types of jib cranes:

Articulating jib cranes are great for complex and confined workspaces, but they often have limited load capacity, typically up to 1 ton.

Wall-Mounted

Wall-mounted jib cranes are a great option for businesses that need to save space. They can be installed very close to the underside of the lowest ceiling obstruction, providing maximum clearance both under and above the boom.

One of the main advantages of wall-mounted jib cranes is that they don't require any type of floor or foundation support. This makes them a great choice for businesses that have limited floor space or need to install a crane in a specific location.

Readers also liked: Jib Crane Wall Mounted

Wall-mounted jib cranes can accommodate spans ranging from 8-30’ and capacities up to 5 tons. They can also be designed to swing around obstacles, under obstructions, or fold out of the way of overhead cranes to ensure no interruption of production.

There are two main ways to mount a wall-mounted jib crane: cantilever and tie-rod supported. Cantilever designs offer the greatest amount of clearance, above and below the boom, while tie-rod supported designs are the most economical means of providing hoist coverage along walls or building columns.

Here are some key features to consider when choosing a wall-mounted jib crane:

- Spans: 8-30’

- Capacities: up to 5 tons

- Rotation: 180°-200°

- Mounting options: cantilever and tie-rod supported

Keep in mind that wall-mounted jib cranes have a major disadvantage: they don't allow for full 360° of rotation. They also require a column or support capable of withstanding the loads, which typically requires a structural engineering survey and approval prior to installation.

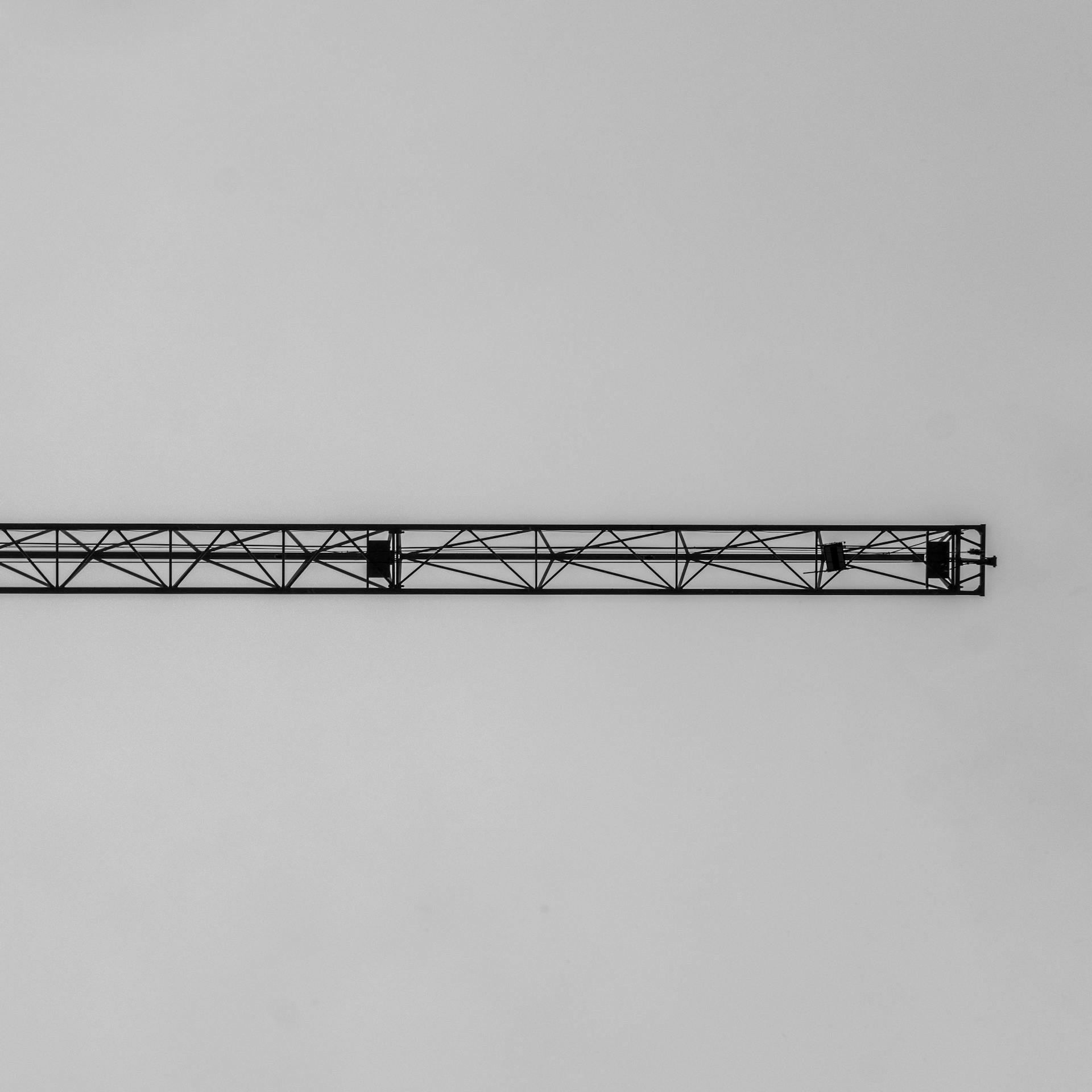

Arm

The arm of a jib crane is its main structural element, supporting the lifting mechanism (hoist). It's the horizontal beam that extends from the mast.

The arm's length can vary depending on the type of jib crane. For example, articulating jib cranes can have spans up to 16 feet.

The arm's design is crucial for the crane's functionality. It's where the load is lifted and positioned, making it a critical component.

Here are some key characteristics of the arm in different types of jib cranes:

In summary, the arm is a vital part of a jib crane, and its design and characteristics play a significant role in determining the crane's capabilities and functionality.

Mast Type

Mast Type Jib Cranes are a cost-effective alternative to freestanding systems, requiring only 6” of reinforced concrete to support them.

They can accommodate spans of 10-40’ and have capacities up to 10 tons, making them suitable for heavy-duty applications.

Mast type jib cranes offer 360° rotation and boom heights up to 40’, providing flexibility and versatility.

There are two types of cantilever design options: Full Cantilever and Drop Cantilever.

Here's an interesting read: Cantilever Jib Crane

The Full Cantilever type is ideal when there are no overhead obstructions, providing maximum lifting capability and clearance underneath.

The Drop Cantilever type allows for clearance for overhead obstructions located below the top of the mast by mounting the boom at a specific height.

Mast type jib cranes are similar to freestanding systems but require an overhead beam or support structure to provide additional support in addition to the foundation.

Here are some key features of Mast Type Jib Cranes:

Key Components

A jib crane's main components include the Reach, which is a horizontal beam that swings back and forth on the trolley, and can rotate 360 degrees in some cases. The Mast/Pillar is the vertical beam that supports the boom.

The Reach is a crucial part of a jib crane, allowing for smooth and precise movement. The Trolley is another key component, transferring the hoist, wire rope or chain, and hooks along the length of the boom.

Here are the main components of a jib crane:

- The Reach

- The Mast/Pillar

- The Movable Hoist

- The Trolley

- Electric Collector Rings (optional)

- Controls

Main Components

The main components of a jib crane are what make it such a versatile and reliable piece of equipment. The Reach, a horizontal beam, is a key component that swings back and forth on the trolley, allowing for 360-degree rotation in some cases.

The Mast/Pillar is the vertical beam that supports the boom, providing stability and structure to the crane. It can be freestanding or mounted on a wall or column.

A Movable Hoist is a device that elevates, positions, and lowers a load, making it an essential component of the jib crane. It can be operated manually or powered by electric, hydraulic, or pneumatic systems.

The Trolley is responsible for transferring the hoist, wire rope or chain, and hooks along the length of the boom. It can be hand-controlled, powered, or pneumatically operated.

Here are the main components of a jib crane at a glance:

- The Reach: A horizontal beam that swings back and forth on the trolley.

- Mast/Pillar: A vertical beam that supports the boom.

- Movable Hoist: A device that elevates, positions, and lowers a load.

- Trolley: Transfers the hoist, wire rope or chain, and hooks along the length of the boom.

- Electric Collector Rings: Assist with rotation and enable continuous 360° boom rotation.

- Controls: Allow operators to control the rotation of the boom and the movement of the trolley and hoist.

- Hook Height: The maximum height of the hook above the base level.

- Rotation Stop: Limits the crane's motion before it collides with a neighboring object.

Working with

Working with jib cranes can boost productivity and enhance workplace safety by lowering employee injuries. They're perfect for high-volume lifts and provide an ergonomic method for transporting material within a workstation or in combination with an existing overhead crane system.

Using jib cranes in industrial settings can be a game-changer. American Equipment designs and fabricates jib cranes for these types of environments.

If you're looking to solve your heavy lifting problems, consider incorporating jib cranes into your workspace.

Here are some types of cranes and hoists you might find useful:

- Gantry Cranes

- Jib Cranes

- Overhead Bridge Cranes

- Workstation Cranes

- Overhead Hoists

Design and Installation

Design and installation of a jib crane is relatively straightforward due to its simple design and construction. Compared to other types of cranes, jib systems require less maintenance and have fewer parts that could potentially break down or fail.

The key components of a jib crane include the reach/boom, mast/pillar, movable hoist, trolley, and rotation. These components work together to provide a reliable and efficient lifting solution.

To ensure a smooth installation process, consider the following factors: the lowest overhead obstruction to determine the maximum hook height, and the need for a rotation stop if the crane is located close to a wall or other obstruction.

For another approach, see: Jib Crane Design

Design

A freestanding jib crane is the most common type of jib system, and for good reason - it's highly versatile and can be installed in any location.

They typically support 360° of rotation, which is perfect for navigating tight spaces and getting the job done efficiently. Boom heights can reach up to 40’, making them ideal for a variety of applications.

One of the key benefits of freestanding jib cranes is their adaptability - they can be base-plate mounted, foundation or inset mounted, making them suitable for different use cases and scenarios.

Here are the three main designs for freestanding jib cranes:

Freestanding jib cranes offer the highest capacities, longest spans, and greatest amount of rotation compared to other jib crane systems. However, they are among the most expensive systems and the most permanent setup due to the special foundation required to anchor and secure the crane.

Foundationless

Foundationless jib cranes are a popular choice for many facilities due to their ease of installation and relocation. They can be slab-mounted and bolted to 6″ reinforced concrete for both indoor and outdoor use.

Foundationless jib cranes are designed for indoor use and can accommodate spans of 9-16′. They typically have capacities up to 1,000 lbs.

One of the benefits of foundationless jib cranes is their ability to be installed quickly, as they don't require a special poured foundation. This can save time and money in the installation process.

These cranes are also easy to relocate within a facility if necessary. They can be easily unbolted and reinstalled in a new location.

Foundationless jib cranes typically offer 360° rotation and boom heights up to 20′. They are a cost-effective option for facilities that need a jib crane but don't require a high capacity.

Here are some key features of foundationless jib cranes:

- 9-16′ spans

- Capacities up to 1,000 lbs.

- 360° rotation

- Boom heights up to 20′

Frequently Asked Questions

What is the difference between a crane and a jib crane?

A crane and a jib crane differ in design, with cranes having multiple points of contact on wheels for mobility, while jib cranes have a single fixed point of contact. This design difference affects their portability and installation requirements.

What is the difference between a jib and a boom crane?

A jib provides lateral movement and precision, while a boom is responsible for height and range, offering flexibility in reaching inaccessible areas. The type of boom, such as telescopic, can further enhance its capabilities.

What is another name for a jib crane?

Another name for a jib crane is a boom crane. Both terms refer to the same type of overhead lifting device.

Featured Images: pexels.com