AC motors can be used as generators, but it's not a straightforward process. In fact, it requires a specific type of motor, known as a universal motor.

To start, AC motors need to be designed with a generator function in mind, which means they need to have a built-in mechanism to convert mechanical energy into electrical energy. This is typically achieved through the use of a commutator and brushes.

AC motors can be used as generators, but they need to be driven by an external mechanical energy source, such as a gasoline engine or a diesel engine.

Suggestion: What Size Inverter Generator Do I Need

What Are Generators?

A generator is a device that converts mechanical energy into electrical energy, and it's pretty much the same as a DC motor in terms of anatomy, except for a few key differences.

The armature in a generator is manually rotated, and as it moves through an external magnetic field, it experiences an induced emf. This is due to Faraday's law of induction.

In an AC generator, the current is already AC, so there's no need to reverse the current direction with a split ring. Instead, a slip ring is used to preserve the AC current.

A DC generator, on the other hand, needs to produce DC current, so a split ring is used to reverse the current direction every 180°. This changes the AC current into DC as it flows through the split rings out the coil.

The key difference between an AC and DC generator is the type of current they produce, not their anatomy.

For another approach, see: Direct Current Electric Generator

Understanding AC Motor Performance

AC motors can be used as generators, but their performance depends on various factors.

The type of AC motor used is crucial, as some are more suitable for generator applications than others. For instance, induction motors are commonly used as generators due to their robust design and high efficiency.

A key consideration is the motor's power factor, which affects its ability to convert mechanical energy into electrical energy. According to the article, induction motors typically have a power factor of around 0.8 to 0.9, making them suitable for generator applications.

Curious to learn more? Check out: Inverter Generator Home

The speed of the motor also plays a significant role in determining its performance as a generator. As mentioned in the article, a motor's speed can be adjusted to optimize its efficiency, with some motors able to achieve speeds of up to 3,000 RPM.

The load on the generator also affects its performance, with heavier loads requiring more power and potentially reducing the motor's efficiency. In some cases, the motor may need to be oversized to handle the load, but this can also increase costs and complexity.

In summary, AC motors can be used as generators, but their performance depends on factors such as motor type, power factor, speed, and load.

Intriguing read: Inverter Generator Not Producing Power

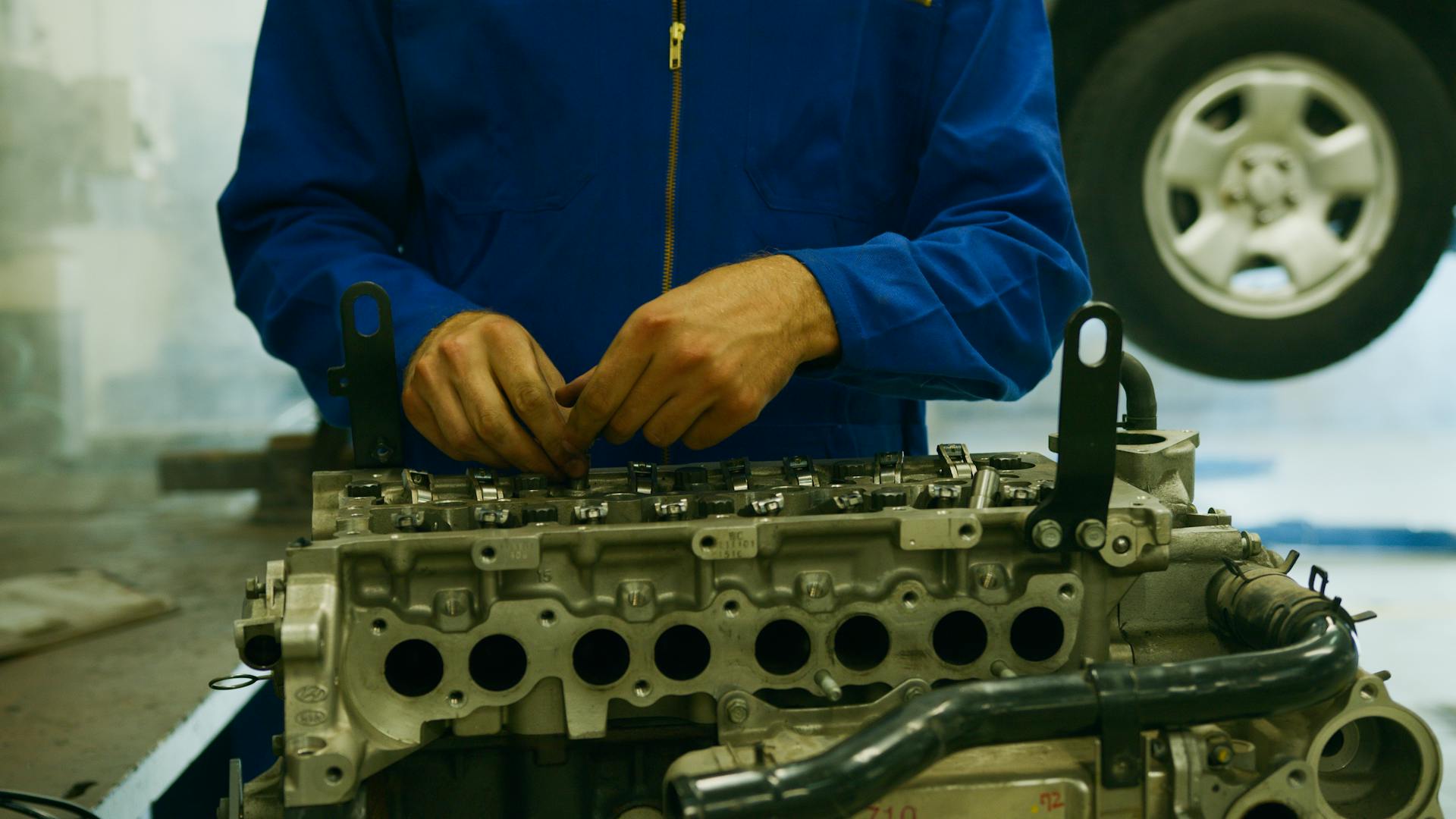

Featured Images: pexels.com